|

|

|

|

| There are many different styles and shapes of drapery. The windows, room and color scheme usually dictate what type of drapery will be used. Most of the styles of drapery available today are shown here. Drapery can be functional to provide privacy, light control and insulation or merely a decorative element. Drapery can be simple or very elaborate. |

| |

Sections:

Go to Drapery Linings

Go to Sun Damage

| Heading types |

The very top of a drapery is called the heading. It is formed by pleating, pinching, gathering, grommeting or tying. A stiffner or buckram is inserted or wrapped into the heading when it needs to be stiff. The type of drapery needed for the window covering will dictate what type of heading and buckram (if any) should be used. Pleated type headings work best for drawing or traversing drapery across an opening and can be used on conventional type traverse rods, pole and ring, or motorized rods. The other types listed are better suited for stationary or non-functioning type drapery.

|

|

Functional Heading types - (Can be drawn across a rod) |

|

|

| Non-functional Heading types - (Designed to be stationary) |

|

| |

| Drapery Linings |

|

Drapery linings provide many benefits for a window treatment.

• Fabric protection from UV (ultra-violet) rays from the sun

• Fabric protection from the general enviroment near or at the window

• Improves the insulating capabilities of the window treatment (R-Factor)

• Provides additional weight, stability and body to the face fabric

• Provides addtional protection to increase life span of a window treatment

• Consistent appearance from the street

| |

| Lining Types |

Cotton Lining

100% Cotton Lining (White & Ivory) |

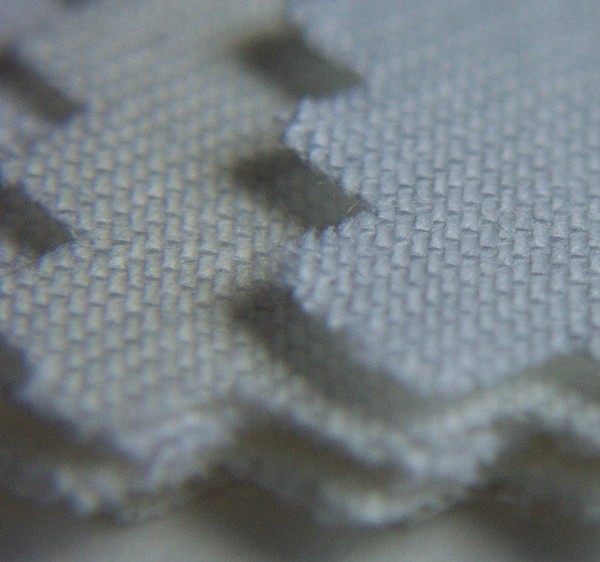

Cotton linings are available in standard widths of 48", 54" and 118" wide. Cotton is soft and has a great feel or "hand" quality and is typically used to line drapery, valance and bedspreads. Cotton linings will deteriorate quickly when exposed to sunlight (UV) for extended periods of time. Drapery oriented in windows with western or southern exposures should be lined in a blended lining to increase the life of the lining. Cotton linings will disinegrate in as little as 2-3 years under extreme exposures. Cotton linings are best used on fabrics with high cotton, linen, flax or silk content as they will grow and shrink at the same rate as the face fabric and will minimize puckering of drapery side hems. |

Poly / Cotton Blend

70/30 Polyester-Cotton blended lining (White & Ivory) |

Poly blends have a stiffer feel than cotton linings due to the polyester content. Polyester is a plastic based fiber that is woven together with cotton to produce the blend. Blended linings are available in 48", 54" and 118". The typical blends available are 50/50% and 70/30%. Using a blended lining is advised in drapery that will receive high amounts of sun or facing a western or southern exposure. Blended linings not only have a stiffer feel but are more vertically stable than cotton linings. Polyester does not absorb moisture or humidity like cotton and therefore will not grow or shrink as dramatically as a cotton lining. Using blended linings to line natural fabrics such as linens, cottons and wools will sometimes produce puckers at drapery side hems. Pre-shrink the face fabric to minimize this occurence. Many silks are dimensionally stable and should not be pre-shrunk. Loosely woven silks can be backed with fusible interfacing for stabilization. |

Interlining

6oz Interlining (White & Ivory) |

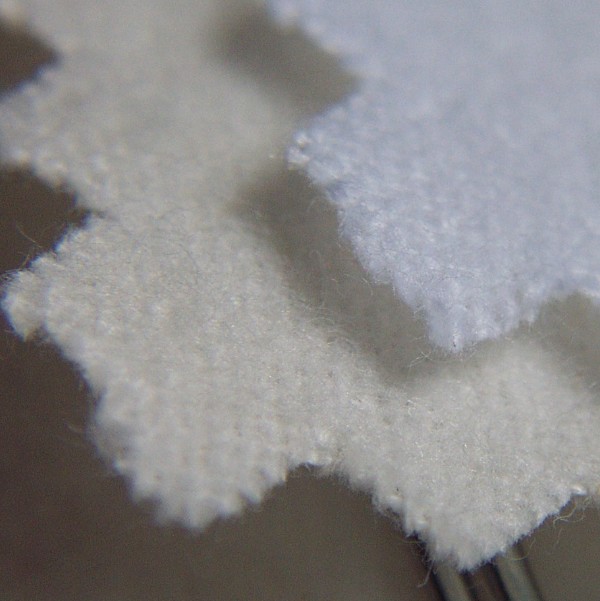

Interlining or "Flannel" as it is commonly known in the trade, is available in 48" and 54" widths and either single knapped or double knapped (fuzzy on one side or two sides). Better quality flannel is double knapped. Both varieties are a 100% cotton based product that is used as a "body builder" to line light weight fabrics by enhancing the body and overall look of a window treatment. Interlining is typically sandwiched between the face fabric and the lining (see above) of the treatment. Careful consideration of interlining color (White or Natural/Ivory) is advised for all light colored face fabrics. Sunlight showing through an Ivory/Natural colored flannel will cast an ivory or gray hue that may distort the color of the face fabric, therefore white colored flannel is most commonly used on all treatments. Perform a simple test by holding the face fabric and linings to the light to see if a color change will occur. All silks should be interlined to provide an addtional layer of protection from the suns harmful UV rays. Interlining is ill-advised on all linens and wools since the knap of the interlining will stick to the face fabric producing ripples and wrinkles that are difficult to smooth out. Use single knapped interlinings to reduce this problem. |

English Bump Lining

(Top is 6oz interlining, middle

and bottom is 12oz bump) White & Ivory shown |

English Bump is the granddaddy of the interlining family and is typically used on light weight face fabrics to produce luxurious and sometimes heavy looking window treatments. English Bump was traditionally used to interline drapery treatments of the British Monarchy and was utilized for its inulating properties rather than looks. The drafty castle is long gone and luxury is now king. Using English Bump dictates different fabrication methods. Since the thick plys of fabric will usually not fit in or under standard workroom equipment used today, much of the assembly requires hand work which dramatically increases the price of the finished goods. |

Blackout Lining

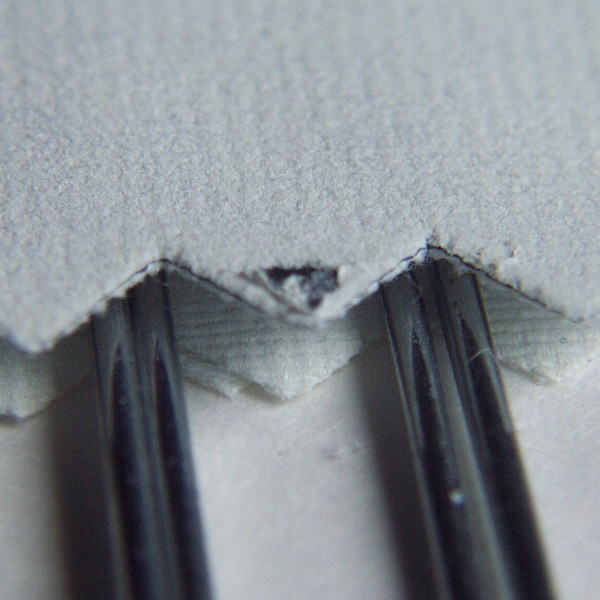

2-Pass Blackout |

|

Thermal Lining

|

|

|

|

|

|

|

| Sun Damage - Effects of Ultraviolet Light |

|

Sun damage on Silk drapery

Sun damage on a wood floor

Sun damaged Furniture

|

The Sun emits UV-Ultraviolet light that damages and breaks down the molecules in various elements. This process is known as Photodegradation. UV light causes our skin to burn and can disinegrate and discolor fabrics, furniture, floors, artwork and many other household items in a matter of months. Window coverings help prevent ultraviolet rays from penetrating into the home providing a barrier to slow or stop photodegradation.

The pictures to the left illustrate the damaging effects of UV damage. Many window manufacturers and window film companies available in the market today claim that the films and Low-E glass block 90-95% of the UV light, but this is simply not so. The wood floor in the picture was installed seven years ago and the doors have Low-E glass in them.

By conducting a simple test, you can determine if the Glass or Film is blocking UV light. Place your hand on a floor or object that has had sunlight shining on it for a period of time. If heat is present or the object feels warmer than items that have not been in the sunlight, then UV rays are present. If plants are growing next to your doors and windows, then addional UV protection should be implemented

For more reading on Photodegradation and understanding light, see these Wikipedia Articles: Electomagnetic Spectrum, Photodegradation, Low-E Glass Coatings. | |

| |

|

|